Product Description

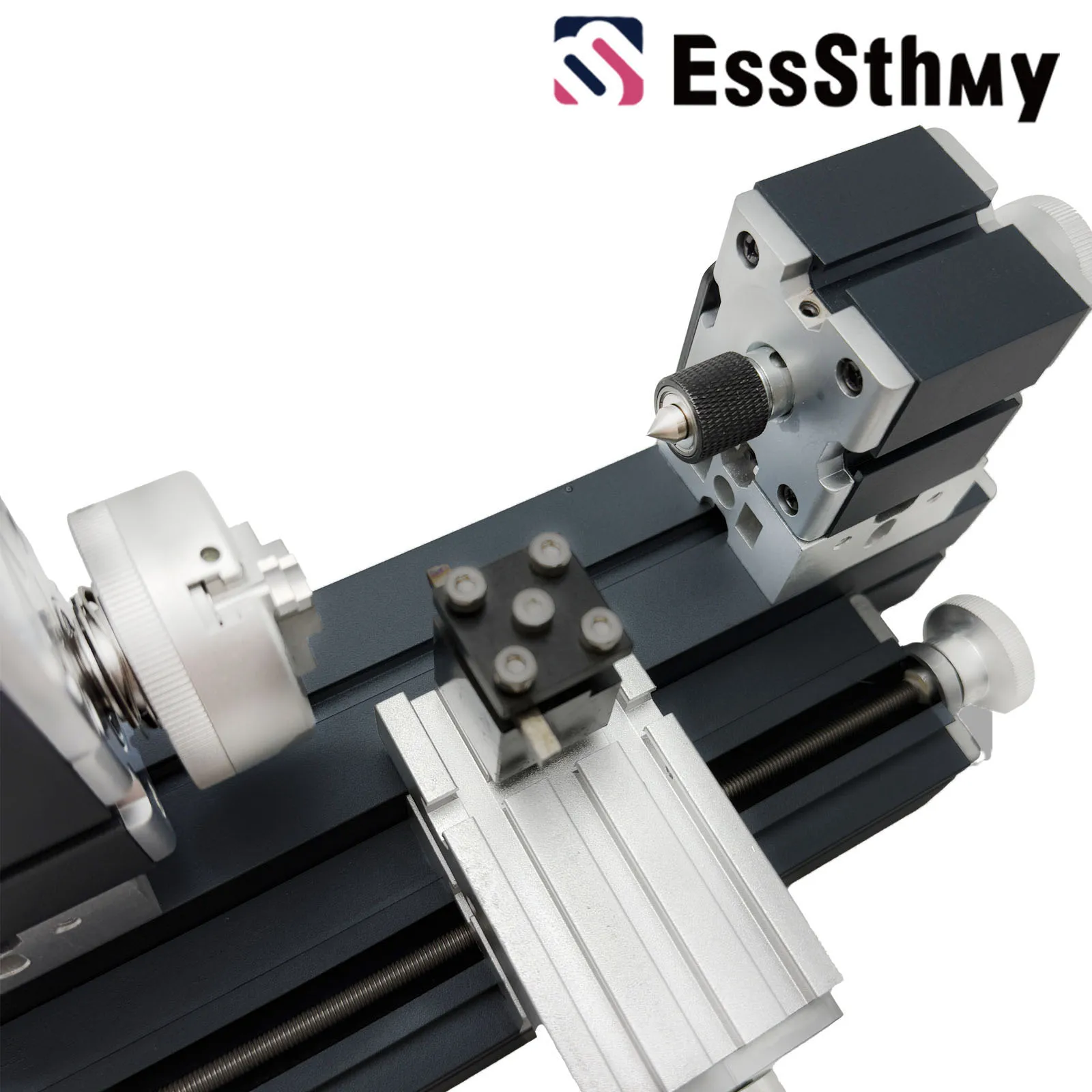

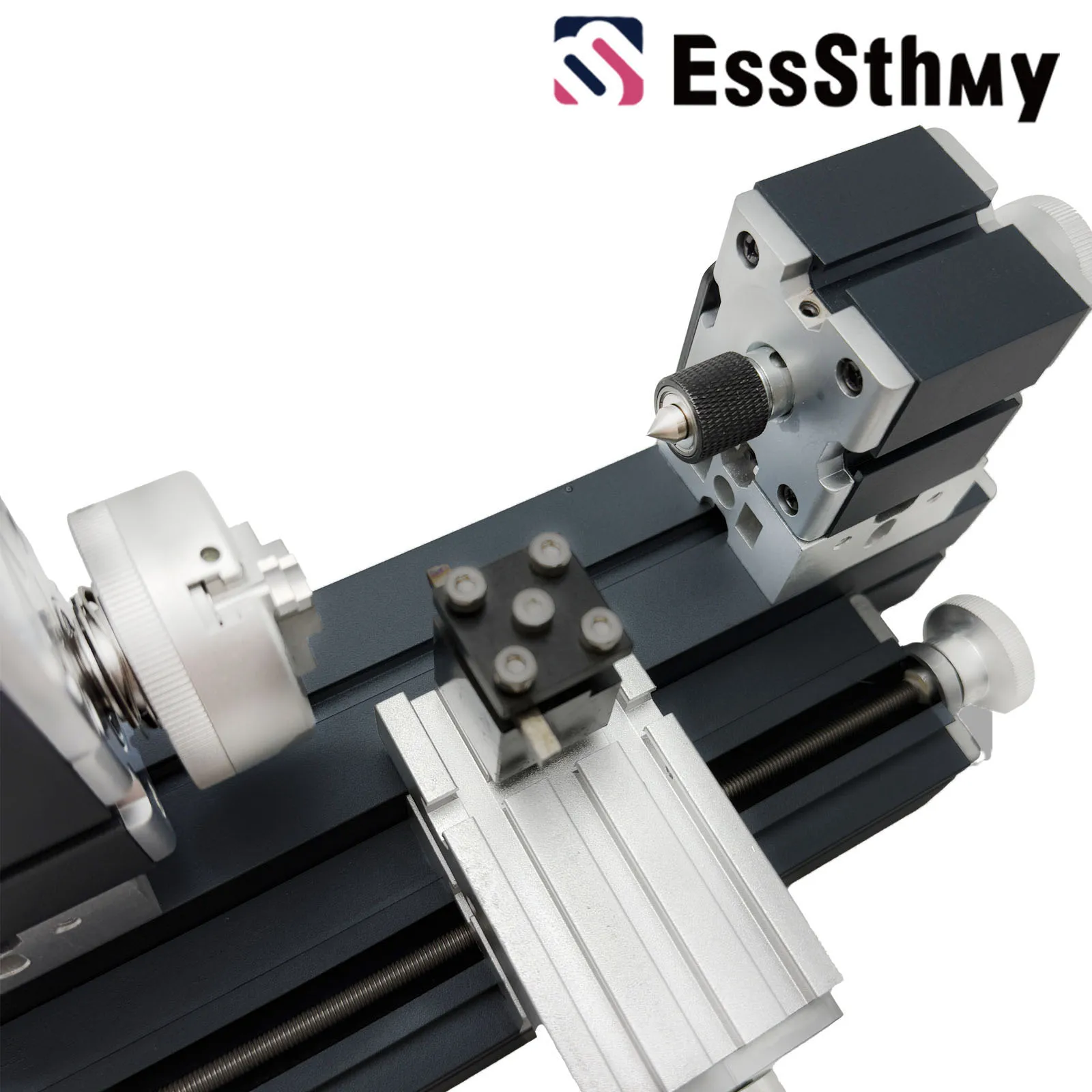

• Heightened Version - Expanded Processing Range: Heightened sliders are added to the lathe motor, base, and tool clamping jaws, enabling a larger turning diameter for enhanced practicality.

• All-Metal Structure: The headstock (with auxiliary fastening holes at the rear), motor box, handwheel, gears, small sliders, long sliders, connecting blocks, three-jaw chuck (optional metal four-jaw independent chuck), belt guard, tool clamping jaws, etc., are all made of metal with no plastic components on the body.

• Chuck Fixing Design: The machine tool chuck adopts a hexagonal nut fixing design to enhance the fastening of clamped tools (such as drills, milling cutters, and wood lathe drivers).

• Design and Protection: The machine tool uses safe rounded corner processing technology to prevent metal parts from scratching the skin.

• Stability and Finishing: The connecting block adopts a dovetail structure to prevent screws from sliding in the holes, and the square nut design avoids gaps caused by excessive vibration during operation, improving stability and service life.

Processing Capability

• Used for turning workpieces.

• Suitable Materials: Wood, soft metals (gold, silver, aluminum, copper), acrylic, plastic, etc., meeting the needs of professional users and amateur DIY enthusiasts.

Application Scenarios

DIY studios, home creative workshops, children's handcraft teaching tools, youth activity centers, school general technology classrooms, science and technology activity room equipment, and student sci-tech creations in museums.

Professional Configurations

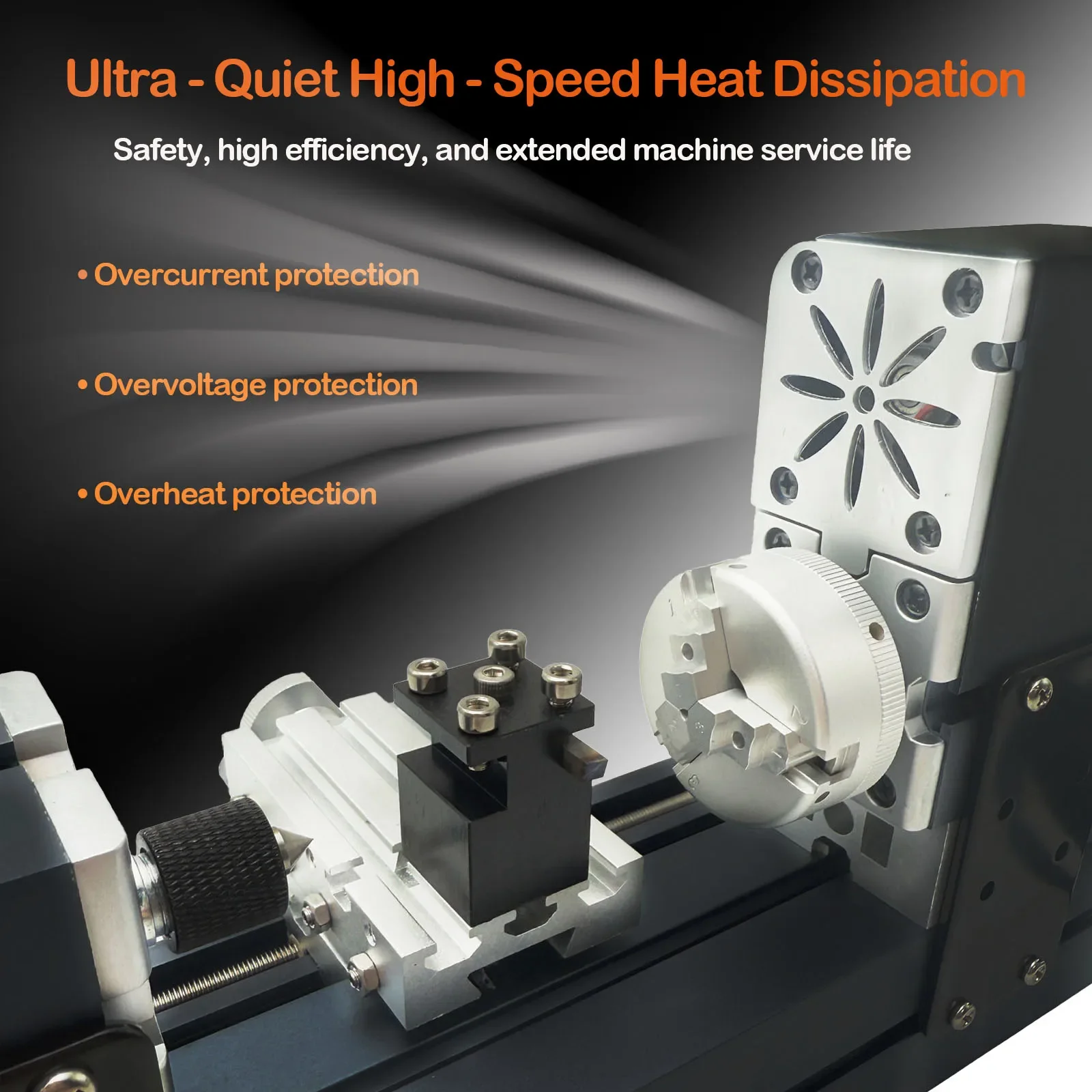

• Custom Ultra-Quiet Motor: Equipped with a custom ultra-quiet, high-speed, low-vibration built-in fan motor, featuring excellent heat dissipation, ensuring quiet and efficient processing, reducing noise pollution, adapting to long-term continuous operation, and balancing precision and durability.

• Protective Transformer: The transformer has overcurrent, overvoltage, and overheat protection functions to ensure safe and stable operation and minimize failure risks.

• Precision Handwheel: The handwheel uses electroplating technology with a 3/4 semi-circular structure for easy operation. The 0.02mm precision scale lines (integrally molded, not pasted) improve workpiece processing accuracy.

Technical Parameters

• Motor speed: 12,000 rpm

• Input voltage/current/power: 12V/5A/60W, switch power supply input voltage: 110V - 240V

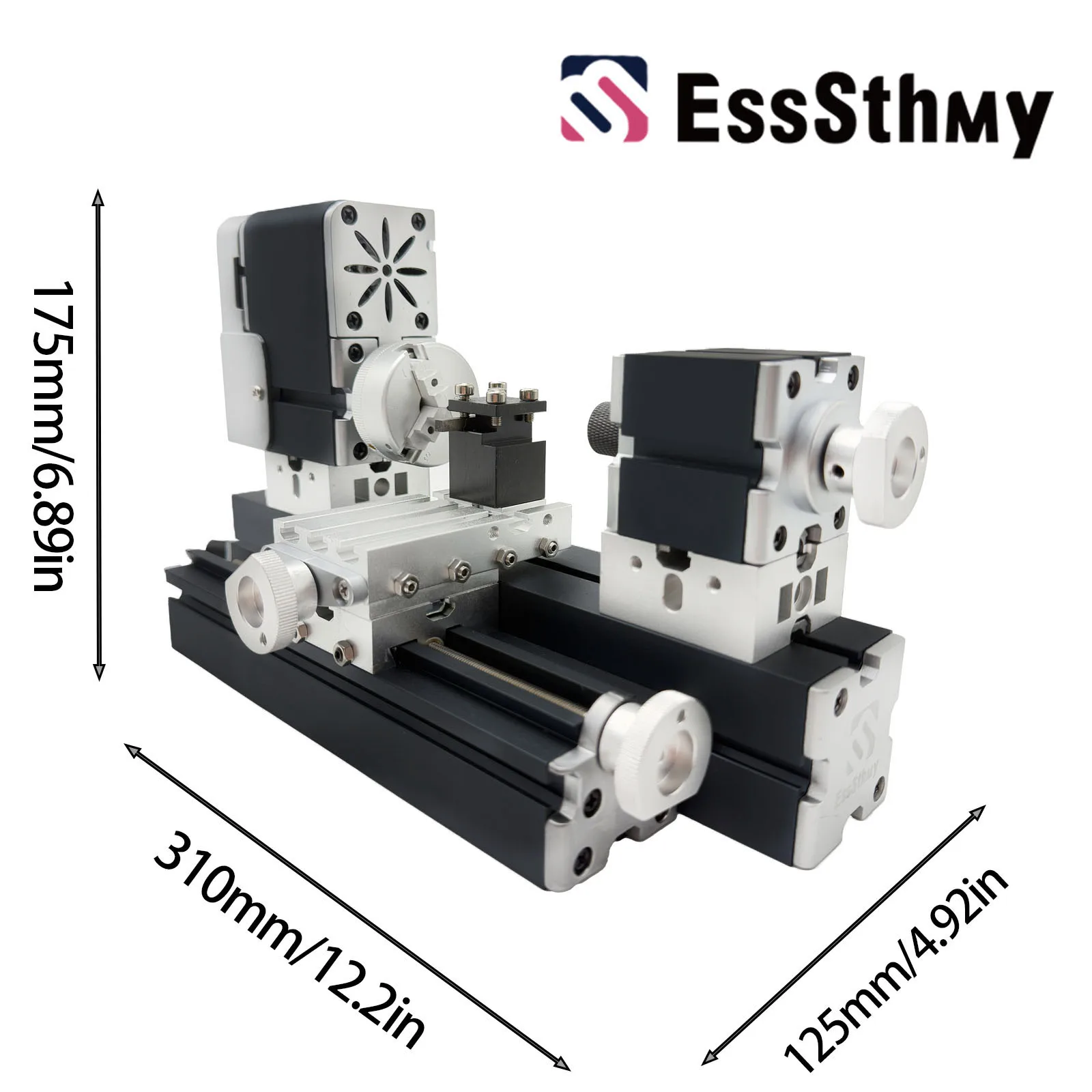

• Maximum processing material diameter: 50mm; length: 150mm

• Center height: 50mm, center distance: 150mm; center positioning precision: 0.01~0.03mm

• X-axis slider stroke: 150mm

• Maximum diameter of workpiece clamped by three-jaw chuck: 50mm. Optional metal four-jaw chuck can clamp special-shaped workpieces (such as square, oval, hexagonal workpieces), expanding the lathe's application range.

• Z-axis handwheel and tailstock handwheel are equipped with 0.02mm precision scale lines (mold integrally formed, not pasted) to improve workpiece processing accuracy.

• The handwheel adopts a 3/4 semi-circular structure for easy disassembly and assembly of the machine tool connecting block.

• Machine tool size: 310mm×125mm×175mm, base size: 315mm×200mm×17mm.

Package Includes:

1 * Mini lathe

1 * Power adapter

1 * Accessory kit

1 * Base plate

1 * User manual

1 * Test piece (wood or aluminum block)